STRÖDTER Handhabungstechnik GmbH

Gabelsbergerstraße 6 • 59069 Hamm (Germany)

Phone: +492385921210 • Fax: -9212121

|

Handling of mass-produced parts is often still done with manual physical strength in parts production, at assembly workstations and in order picking

Logistics areas are taken care of. |

|

more economical solution. |

|

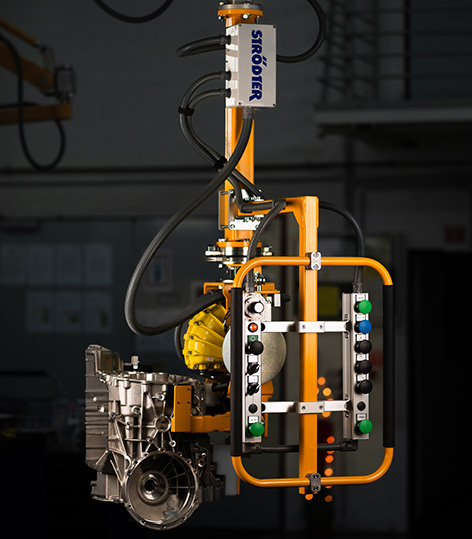

the parts can be moved floating easy and ergonomic. STRÖDTER supplies complete systems with product grippers. |

Some parts can also be gripped with mechanical hooks or fork tools. The choice of

The right system depends on the requirements of the respective process. Especially in mechanical engineering, it is often necessary

heavy machine parts are handled sensitively, gently and precisely. Conventional crane systems are not suitable for this because of their

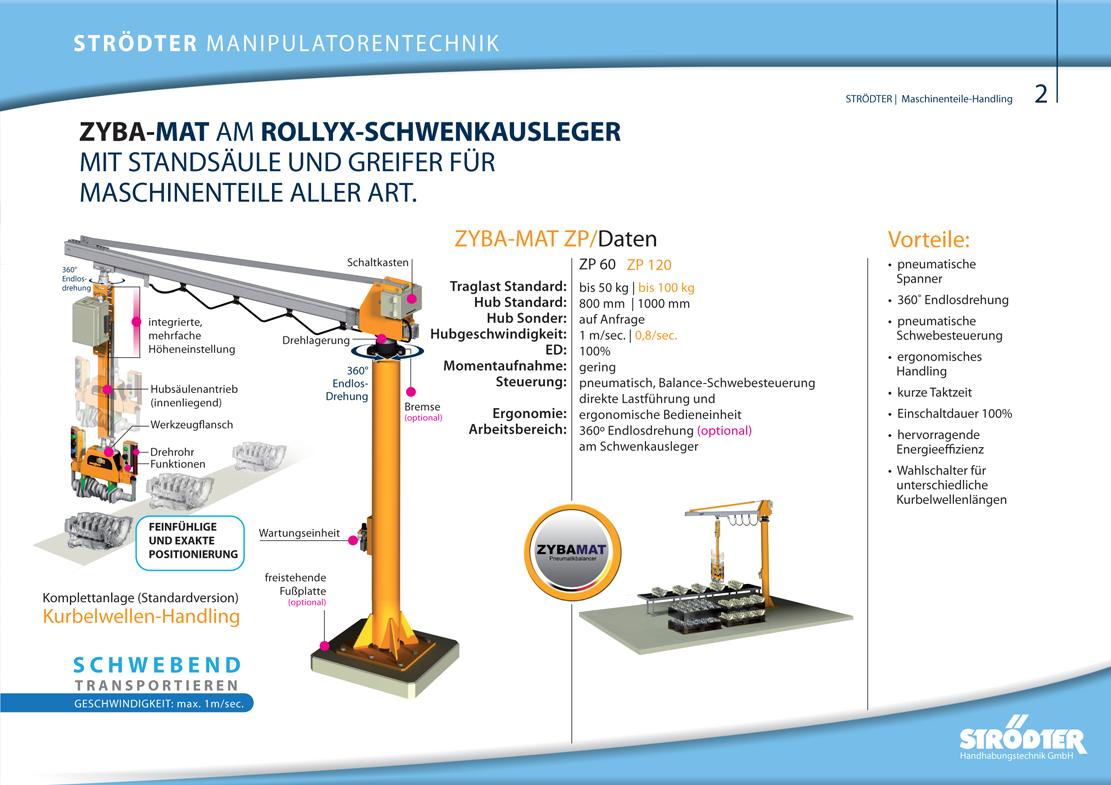

sensitive control and the slow lifting speed are unsuitable. Suitable for the sensitive and precise fit

The machine components are balance handling−manipulators. The balance-floating control allows the components

can be guided floating, transported quickly and installed sensitively using human sensors. |

|

|

|

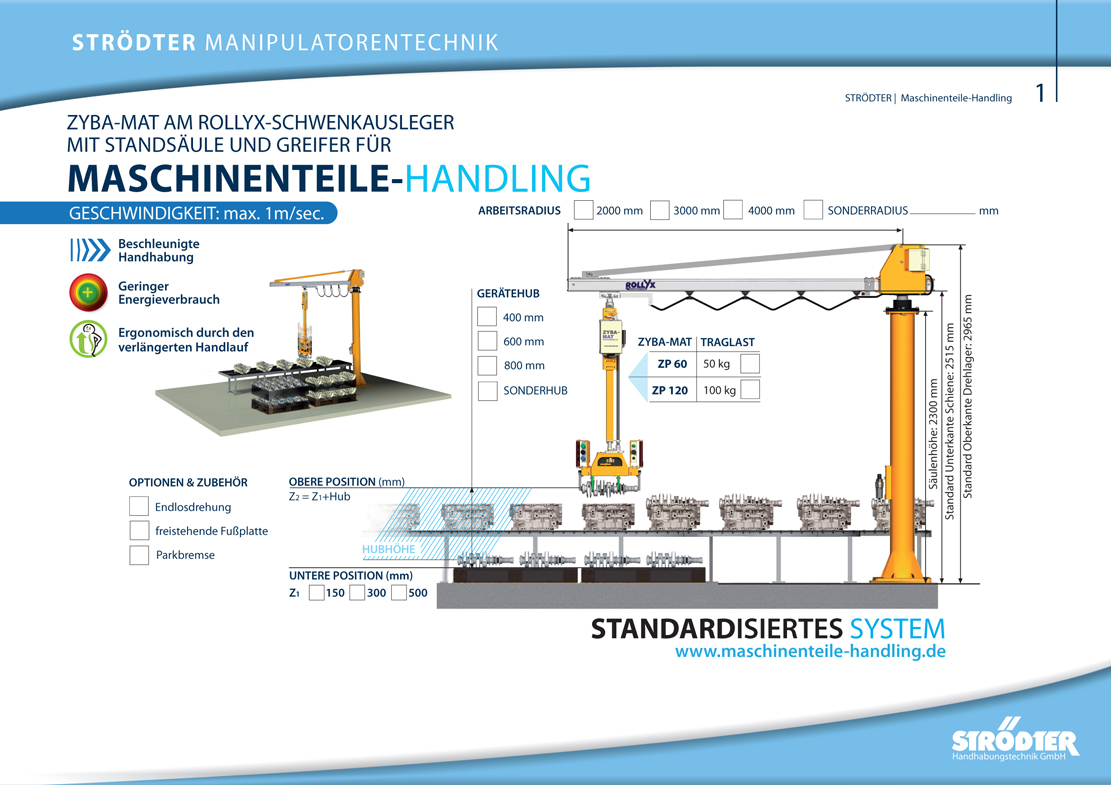

Efficient Machine Parts Handling.

Safe Lifting and Transport. |

|

From pre-assembly to surface treatment to final assembly and packaging. Whether it's about hanging components quickly and safely

or precisely re‑hang: STRÖDTER offers proven solutions for your production line. |

||

|

||

Increase productivity, quality and occupational safety in your company — trust STRÖDTER, your specialist for boiler handling, Pressure vessels, hot water heating boilers and enamelled metal construction parts. » to the boiler handling brochure (PDF) |

||

|

In the manufacturing of railway wheelsets, the precise and safe handling of heavy wheel discs plays a crucial role.

STRÖDTER Handling Technology offers manipulator systems specifically developed for the requirements of wheelset production.

Our solutions enable the ergonomic and safe handling of railway wheels weighing up to 1,200 kg − from raw discs to fully finished monoblock wheels. |

|

Typical wheel sizes range from around 700 mm to over 1,250 mm in diameter. STRÖDTER offers field-proven systems that integrate seamlessly into modern production processes. Rely on proven technology for handling your DIN EN 13260 compliant wheel discs − for increased safety, efficiency, and ergonomics in your production. Quick and easy inquiry... |

||

Hovering elevates the experience above lifting!

|

|

|

|

|

|

| Many industrial sectors produce manufacturing parts internally in order to maintain control over product quality and delivery times. This is particularly the case in industries that require specialized components or special quality standards required are. If you look specifically at the area of machine parts handling, you will notice that many of these products are sensitive to incorrect handling handling. The STRÖDTER handling technology is tailored precisely to this area of appropriate handling specialized. Here are some industrial areas in which manufacturers often produce many production parts for production themselves and are dependent on this Produced quality of the products to maintain: | |

| Automotive industry: Automobile manufacturers often produce a variety of components such as engines, transmissions, chassis and electronic parts in-house

to better control the quality and the production chain. STRÖDTER built-in manipulators have been supporting this for many years. |

Aerospace industry: Due to the strict safety and quality standards, many critical parts such as engines, avionics, optical Components and structural components manufactured internally. |

| Mechanical engineering: Manufacturers of industrial machinery and equipment often produce key components in-house to ensure the performance and reliability of their products ensure. | Energy generation: The energy generation industry, whether in the production of electricity through power plants or renewable energies, is often highly specialized Parts manufactured internally to ensure the operation of the systems. |

| Medical technology: In the production of medical devices and instruments, many components are manufactured internally to meet strict regulatory requirements to fulfill and ensure quality. | Defense Industry: The defense industry often manufactures its own parts to ensure that critical defense equipment meets high quality and standards Meet safety standards. |

| Electronics Industry: Electronics manufacturing often produces printed circuit boards, semiconductors and other components in-house to maintain control over the Maintain product quality and reliability. | Chemical and pharmaceutical industry: When producing chemical products or active pharmaceutical ingredients, the internal production of key components is important important to ensure the quality and safety of the products. |

| Heavy industry: In steel and metal processing, many components are manufactured so that the raw materials can be processed internally to meet specific requirements of customers. | Food and Beverage Industry: In some cases, manufacturers build specialized processing equipment or packaging machines in-house to accommodate the To optimize the production process. |

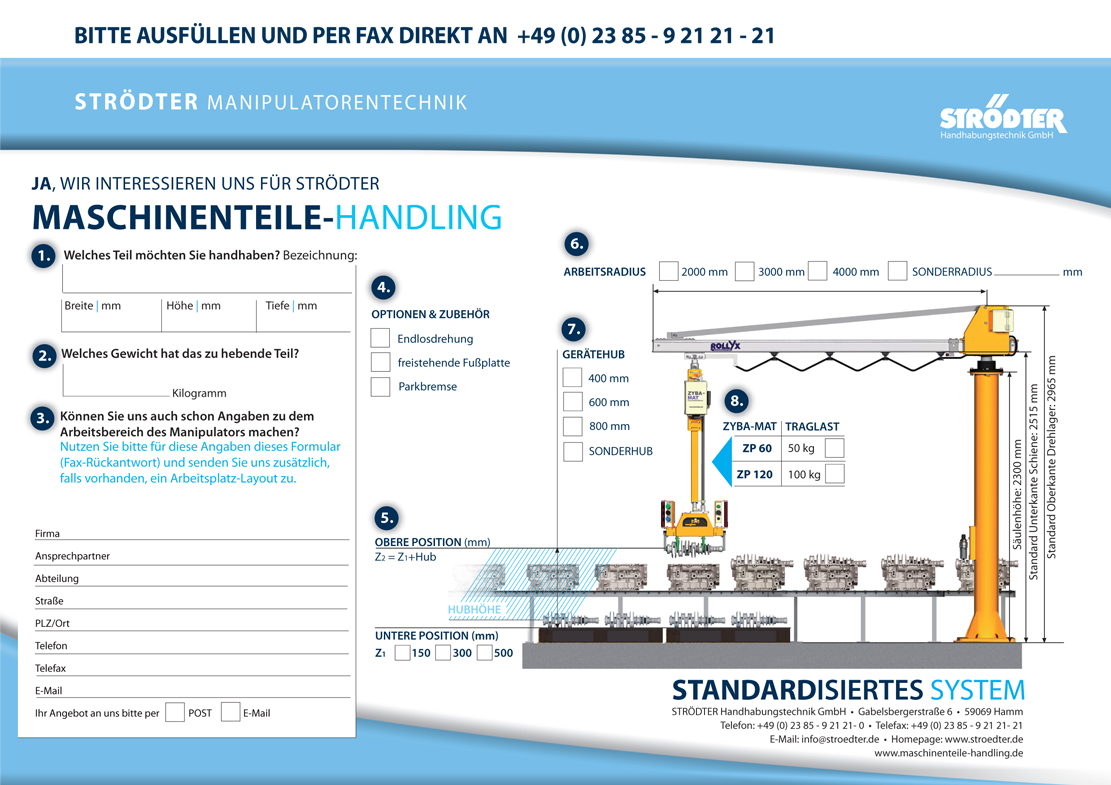

| Download: Maschinenteile-Handling.pdf | FAX.pdf | IMPRINT | Phone: +492385921210 | www.maschinenteile-handling.de | |

| |

|